Smooth Communication

Quick Feedback

Good Quality

Responsible

...

Thousands of Customers from 100+ Global Countries said to us. Here is what we've been doing to gain their, and also to win your trust.

Quality Management of the Supply Chain

Ensure The Stability of Raw Materials

1. Gradually Establish a Complete Supplier Verification Mechanism

Set raw material standards according to product requirements, such as evaluating the capabilities of suppliers through annual audits and daily non-conformities and formulating follow-up improvement plans.

2. Incoming Material Inspection

We have established and gradually improved standards for all raw materials used. Inspect incoming materials according to standards and strictly controls the quality of raw materials put into production, such as physical and chemical indicators like appearance, weight per unit area, corona value, solid content, and moisture content.

3. Production Process Evaluation

For self-produced adhesives, self-produced base fabrics, etc., further quality control of raw materials is carried out to ensure the consistency of raw materials.

4. Strictly Supervise Changes in The Processes and Equipment of Suppliers

We will comprehensively review whether the incoming materials meet the company's standards and visit the suppliers to confirm the stability of their processes. After passing steps tests, the technical department will make a judgment and send the samples to customers for confirmation before formal use.

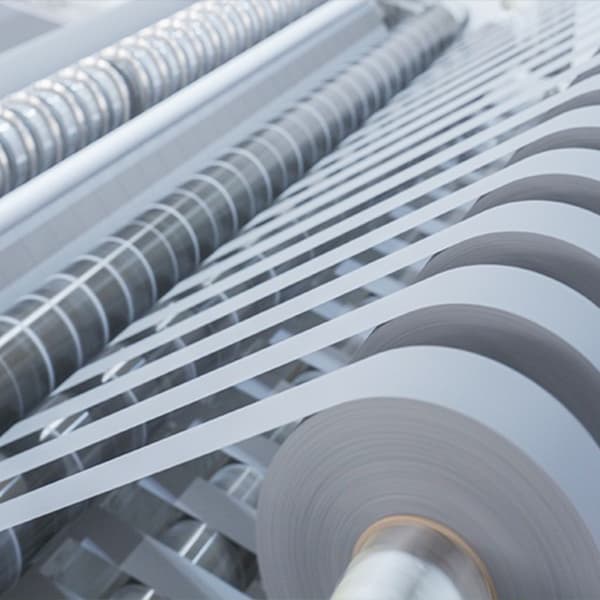

Self-Research and Self-Production of Main Raw Materials

Adhesives Production

Our current annual output of adhesives is 9,120,000 kgs, including water-based adhesives, oil-based adhesives, TPU adhesives and etc.. A factory with an annual output of 50,000,000 kgs of adhesives is under construction and is expected to be completed in near future.

Micro-Glass Bead Treatment

We developed our own technology of surface treatment in order to ensure the best quality. Our Huzhou factory is able to treat 4,000,000 kgs of glass beads every year.

Quality Control in the Production Process

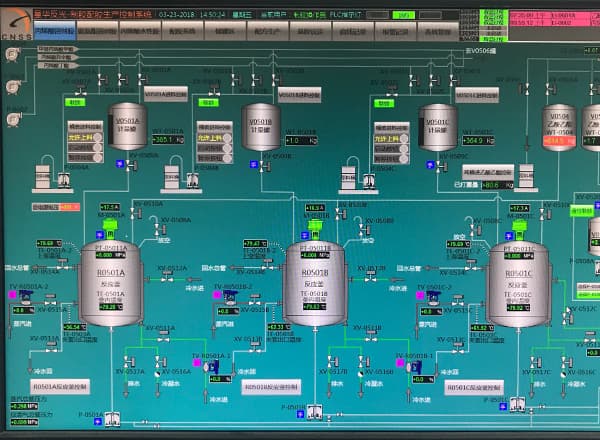

1. Stable Process Control

Strictly control the production process in accordance with process requirements, achieving a coating accuracy control within the micron level, a bead-planting temperature deviation within ±1℃, and a drying temperature deviation within ±3°C.

2. Stable Operation of The Equipment

Before production, the production department and the equipment department will conduct cross-inspections of production equipment to ensure that the equipment functions, parameters, and accuracy meet the process requirements. During the production process, pay attention to abnormal equipment operations in a timely manner, such as abnormal noises and jams.

3. Process Quality Control

Establish a complete process quality parameter control management procedure, including control contents such as product brightness, quick-wash performance, weight per unit area, thickness, and appearance, and monitor abnormalities in real-time.

4. Environment and Personnel Control

Strictly require operators to operate in accordance with the provisions of the "Operation Instruction Manual", and they can only go on duty after passing training to ensure product quality and safety. At the same time, pay attention to environmental changes to reduce the impact of the environment on products and ensure product stability.

5. Production Automation

The production equipment is continuously upgraded. Each new generation of factories has a significant improvement in automation. Currently, some production sections have achieved full automation, further guaranteeing the stability of product performance.

Quality Inspection And Control of Finished Products

1. Performance Testing

Establish a complete set of product quality evaluation items, such as testing methods and standards for washing, dry-cleaning, brightness, rain-proof, flame-retardant, color fastness, aging, etc., to ensure that the shipped products meet the performance indicators and customer requirements. The quality management department has also established key performance CPK and PPK data to evaluate the stability of evaluation methods.

2. Appearance Control

After the production department conducts a comprehensive visual inspection, the quality inspection department conducts spot checks according to the specified ratio to ensure that the appearance quality of the shipped products meets the standard.

3. Packaging Control

From the perspective of actual user use, simulate the transportation scenario, and design corresponding anti-damage, moisture-proof, and anti-pollution packaging for products to ensure that the products are delivered to customers intact.

200+ National Patents

Invention Patents 60+

Utility Model Patents 90+

Product Design Patents

In-depth Research and Mastery of Technology in Products, Processes, and Equipment, With Multiple Patents.

Cooperate with leading universities and set up "Chinastars Reflective - Zhejiang University Reflective Material Research Center".

Our Commitment to Sustainability & Social Responsibility

Sustainable & Eco-Friendly Practices

1. Eco-Conscious Materials & Energy Efficiency

- Water-Based or solvent-free reflective coatings to reduce environmental impact.

- Recyclable or biodegradable reflective products to minimize waste.

- Energy-efficient production using lower-temperature processes and advanced machinery.

2. Non-Toxic & Environmentally Safe Chemicals

- Free from phthalates and other hazardous substances for safer use.

- Eco-Friendly auxiliaries to reduce wastewater pollution.

- Certified by OEKO-TEX 100, ensuring non-toxic materials.

Green Factory & Carbon Footprint Reduction

Our Jingshan factory is recognized as a "Hangzhou Green Low-Carbon Factory".

Using RTO (Regenerative Thermal Oxidizer) to reduce harmful emissions

Implementing solar power generation to lower reliance on fossil fuels

Utilizing energy storage systems for optimized energy efficiency

Durability & Waste Reduction

- High-Quality reflective materials to minimize frequent replacements.

- Continuous R&D for more durable, high-performance reflective materials.

- Reducing waste discharge and promoting sustainable production.

Significantly Extending the Lifespan of Garments.

- UP TO 50-100 CYCLES Water Wash durability of reflective materials

- UP TO 50 CYCLES Industrial Wash

Employee Care & Social Responsibility

Regular Training Programs on Production Safety and Skills Enhancement.

- Providing a safe and healthy workplace in compliance with occupational safety standards.

- Fair employment policies to guarantee labor rights and equal pay.

- Supporting community development through active participation in public welfare projects.