CNSS reflective heat transfer film can be heated on various substrates like polyester, oxford, stretch fabric, elastic band, webbing etc.. It can be widely used on safety vest, sportswear, shoes, hats, bags and PPE etc.

Reflective heat transfer film can also be cut by plotter or laser machine into GRAPHICS, CHARACTERS and LOGOS and transferred to all kinds of fabric base by heat and pressure. Personalize your NAME, TOWN, STATE with our reflective heat transfer film. Let us create a logo design that is uniquely yours.

Comparison Table

| CNSS Reflective heat transfer film | |||||||

| Product No. | Product Name | Adhesive side liner | Reflective side liner | Initial Average R1 | Home Wash Cycles | Application | Certificates |

| CS 4002 | High heat transfer film | None | Clear polyethylene | R>260 | Up to 25 cycles | Polyester or knitted Non-stretchable fabric | |

| CS 4002 for graphic design | High heat transfer film for graphic design | None | Thickened clear polyethylene | R>260 | Up to 25 cycles | Polyester or knitted Non-stretchable fabric, esp. for lettering and logo | |

| CS 4003 | Silver heat transfer film | None | Clear polyethylene | R>420 | Up to 50 cycles | Polyester or knitted Non-stretchable fabric | EN ISO 20471,ANSI/ISEA 107-2010,AS/NZS 1906.4,CSA-Z96-02 etc. |

| CS 4003E | Elastic silver heat transfer film | Blue polyethylene | Clear polyethylene | R>420 | Up to 50 cycles | Stretchable fabric or elastic band | EN ISO 20471,ANSI/ISEA 107-2010,AS/NZS 1906.4,CSA-Z96-02 etc. |

1Measured by Chinastars on new product at +5.0°entrance and 0.2°observation angles.

Application Instructions

-

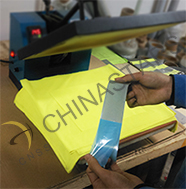

Step 1 Remove adhesive side liner, exposing dry adhesive. Do not remove reflective side liner.

-

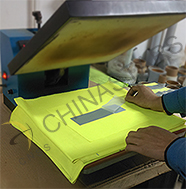

Step 2 Place the heat transfer film on fabric with adhesive side down and apply heat and pressure as described below.

-

Step 3 Allow heat transfer film to cool to room temperature. Remove the reflective liner by lifting one corner and pulling (180°angle) in a continuous, smooth manner.

| CNSS Reflective heat transfer film | ||||||

| Machine Product No. | Heat Press machine | Heated roll laminator | ||||

| Temperature | Dwell time | Line Pressure | Temperature | Rotate speed | Line Pressure | |

| CS 4002 | 140-160℃ | 8-20 seconds | >0.5kg/cm² | 120-140℃ | 4-8 m/min | >2 kg/cm² |

| CS 4002 for graphic design | 140-160℃ | 8-20 seconds | >0.5kg/cm² | 120-140℃ | 4-8 m/min | >2 kg/cm² |

| CS 4003 | 140-160℃ | 8-20 seconds | >0.5kg/cm² | 120-140℃ | 4-8 m/min | >2 kg/cm² |

| CS 4003E | 150-170℃ | 10-20 seconds | >0.5kg/cm² | 130-150℃ | 4-8 m/min | >2 kg/cm² |

Video demonstration on YouTube: http://youtu.be/uk2tS_fmHS0

Application Instructions

1. The lamination temperature, time, speed and pressure listed above shall be used as a guide. For each fabric, the proper conditions much be tested beforehand to assure adequate adhesion and physical performance.

2. Work on a flat surface where heat and pressure can be applied. Do not heat over seams and stitches.

3. Remove adhesive side liner (if the product has one) before placing heat transfer film on fabric (substrate) and apply heat and pressure.

4. Do not exceed lamination temperatures listed above because the clear polyethylene liner may become difficult to remove and affect the physical performance. If high temperatures are required for bond durability, follow lamination steps 1-3 using recommended temperature, remove paper liner, and then laminate again at the higher temperature (using a non-stick slip sheet or cotton fabric to protect reflective surface).

5. When do laser engraving or lettering, it is highly recommended to dispose all surrounding graphics or letters to avoid further losses, if the physical performance of the peeled-off part is not good enough.

6. Care instructions: Use neutral detergent in hand wash. Do not pre-soaking. Hot water wash is allowed around 40℃. Do not use detergent that contains bleach, acid or alkali.

7. Use within one year from the production date.